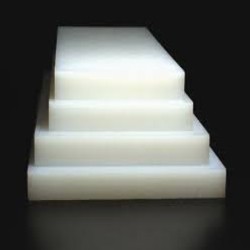

Machined Plastic Parts

About UHMW and HDPE UHMW(Ultra High Molecular Weight) polyethylene plastic is known for its exceptional impact strength, making it one of the most durable thermoplastics available. It also offers outstanding abrasion resistance and tensile strength. Among all polyethylene materials, UHMW stands out with the highest impact strength. It outperforms carbon steel by a ratio of 10 to 1 in some applications. Additionally, it resists stress and cracking while boasting a low coefficient of friction, making it self-lubricating. These properties make it ideal for sliding applications, rough surfaces, or any scenario where reducing friction is essential. HDPE (High Density Polyethylene), while slightly lower in tensile strength compared to UHMW, offers excellent chemical resistance and minimal moisture absorption. This material is widely used in industries that demand impact resistance, high tensile strength, and resistance to chemicals and corrosion. In machining applications, it achieves a finer finish than UHMW, though both materials are easy to machine. Today, various grades of UHMW and HDPE are available to meet specific application needs. For example, anti-static grades of UHMW (AS/UHMW) are used to produce parts that prevent the build-up of electrical charges, making them ideal for sensitive environments. A.L.Plastics | Marion Collection | Acrylic Depot