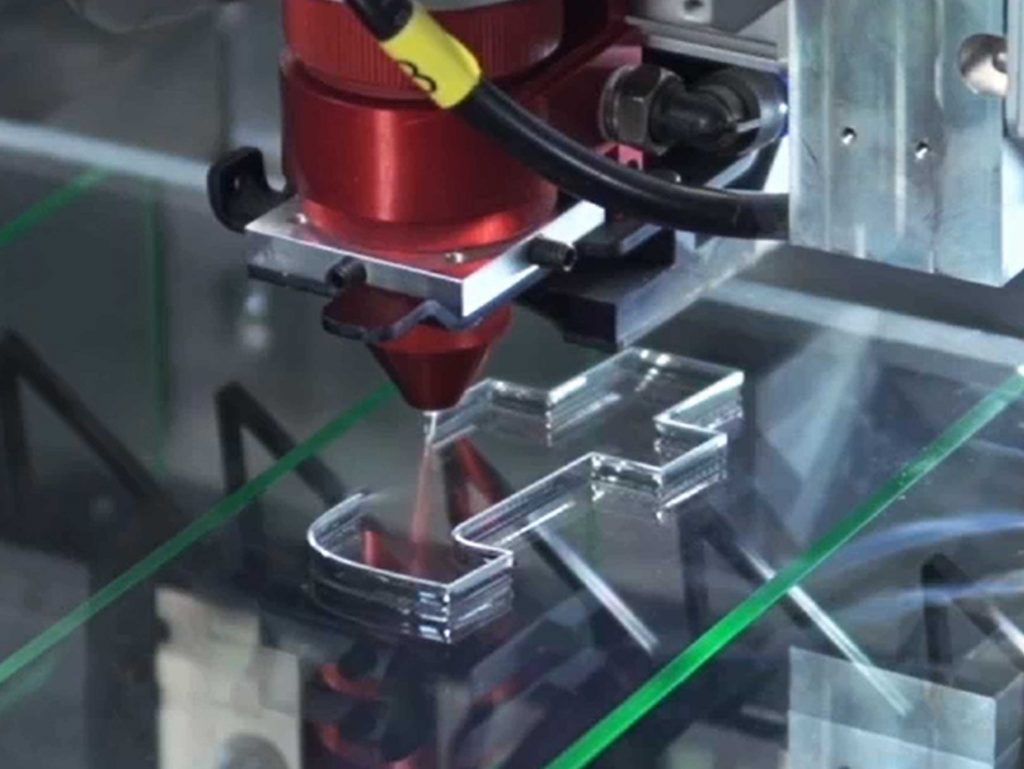

Laser cutting process for acrylic ( Lucite ) sheets

1. Define Your Cutting Expectations Before cutting acrylic, you must first determine your expectations for the final product. Does the end result need a flame-polished, optical-quality finish? Or is the part intended for mechanical use, where edge quality is less critical? This decision will help you choose the appropriate cutting method. For example, if edge quality isn’t a priority, you can save significant time by opting for a less refined cut. 2. Understand the Laser Cutting Process Laser cutting works by vaporizing the solid acrylic material. The laser’s energy causes the acrylic to transition from solid to liquid and then to vapor. This process involves minimal chemical degradation, ensuring a clean cut. However, laser cutting generates a large amount of vapor, which requires an efficient vacuum system to remove it. Importantly, the vapor produced during laser cutting is highly flammable. To prevent accidents, never leave the laser system unattended when cutting acrylic. 3. Use Airflow to Enhance Cutting Quality A gentle stream of air or nitrogen helps blow vapor away from the cutting area. This airflow not only prevents the vapor from igniting but also solidifies the liquid along the cut line. When done correctly, it creates a glossy, flame-polished finish on the cutting edge. However, excessive air pressure can disrupt the solidification process, resulting in a frosted or wavy edge. To avoid this, use an air assist pump with a variable pressure regulator. This allows you to control the airflow and achieve the best results. 4. Choose High-Quality Materials The foundation of a good cut lies in the quality of the material. Using name-brand acrylics ensures optimal results, as these materials are consistent and reliable. Trusted brands like Trotec offer superior performance and are recommended for achieving professional-grade cuts. Brand Manufacturer Plexiglas® / Acrylite® Evonik Perspex® Lucite Altuglas® Akemar Plazit® Plazit Quinn® Quinn Oroglas® Oroglas Types Of Acrylic There are two main types of acrylic that you will commonly encounter, cast and extruded acrylic. These two types of acrylic have slightly different chemistry and are manufactured differently, which results in vastly different cutting characteristics. For most applications, cast acrylic is probably the right material for you, but under specific circumstances extruded acrylic might have its advantages over cast acrylic. The main differences are listed in the table below. Cast Extruded General Many colours available More expensive More thickness’s available (2mm to 200mm) Greater thickness tolerance (>±5%) Less colours available Cheaper Less thickness’s available (30μm to 25mm) Lower thickness tolerance (<±5%) Laser Engraving has high contrast No bur on cut edge High molecular-weight Needs more power – higher melting point Parameters more critical for flame polishing Engraving has low contrast Sharp bur at laser cut line Low molecular-weight Needs less power – lower melting point Parameters not as critical for flame polishing Laser Power As a typical rule of thumb for every 10 Watts of power you will be able to cut 1mm / 0.04 inch of material. This will give you the ability to flame polish your cuts and give good production speed. That doesn’t mean you can’t cut 12mm / 0.5 inch with a 60 Watt laser, this is still possible, but the quality of the cut will not be nice and the process will be much slower. As a general rule, more power is always better; this gives you the versatility to cut extremely fast on thin materials and give you much better cut quality on thicker materials, peak power is the key! Frequency Depending on the material and the type of cut you would like to achieve, the frequency value will change. Flame Polished Cut Common to start with high frequencies (20 to 25 kHz) for cast acrylic. Common to start with low frequencies (2-5 kHz) on extruded acrylic. Separation Cut Common to start with frequencies (9 to 12 kHz) for cast acrylic. Common to start with frequencies (5 to 10 kHz) for extruded acrylic. By decreasing the frequency of the laser you are essentially reducing the cutting energy of the laser, this is done by reducing the amount of laser pulses over a given time frame. This can however help reduce flaming, decrease boiling but does result in slower cutting speeds. The cutting speed is defined by two factors, the quality requirements and the laser power. The typical types of cuts and their speed are shown in the image above. The light blue line represents a separation cut, which is a cut with no preference for edge quality. The second type of cut is represented by the dark blue line which is a quality cut. As you can see there is a large discrepancy in speed of the cut depending on the quality level you would like to achieve with a given thickness of material. There is also a linear increase in speed as the power of the laser increases. For example a 400W laser cutting 10mm thick acrylic will be twice as fast as a 200W laser cutting the same material. Lenses and Focus Lenses are an important factor in the cutting process of acrylics, they have different focal lengths which affect their beam radius and waist length. Without getting too technical, the lenses are responsible for the shape and quality of the cutting edge. For materials up to 20mm / 0.75 inch in thickness you should use a 2.5″ lens if the power of your laser permits this. For lasers with power levels <120 Watts you will notice a dramatic cut quality increase if you linearly increase the lens focal value as the material thickness increases. Trotec laser offers lens options from 1.5″ all the way up to 5″ versions. For materials of 3 to 6 mm (1/8 to 1/4 inch) in thickness you will be able to cut faster using a 2″ lens. For material above 20mm / 0.75 inch in thickness or if your laser power exceeds 200 Watts, using a 5″ lens will give best results. As for focus, for best results, follow these rules. Do not defocus the laser if the material you are

Cut to size plastic and acrylic fabrication

Uses for Plastic Sheeting Acrylic is incredibly versatile and has a wide range of uses. Many household projects and home improvements benefit from colored or clear plastic sheets. For example, homeowners often use high-impact, shatterproof acrylic as a cost-effective and safer alternative to glass for shed or greenhouse windows. Other popular uses include kitchen splashbacks, countertops, table protectors, and picture framing. Larger projects, such as shower tanking and wet-room installations, have also become increasingly common. These durable and stylish sheets can be cut to any size and come in virtually any color, making them both practical and fashionable. Colors and Other Options In addition to clear acrylic (equivalent to Acrylite®), we offer a wide range of colored plastics, including silver and gold mirror finishes. Our plastic sheets (acrylic and polycarbonate) are available in both transparent and opaque varieties. Simply provide the dimensions, color, thickness, and transparency preferences for your custom acrylic sheet order. Cut to Size After receiving your order, we cut and finish the edges of your bespoke plastic sheet to meet your exact requirements. We then wrap and protect your sheets to ensure they arrive at your door in pristine condition. Acrylic sheeting offers several advantages over other materials. It is lightweight, easy to clean and maintain, and can be molded into almost any shape. These qualities make acrylic sheets a perfect choice for various creative and functional projects. From Simple Shapes to Complex Designs We don’t just cut acrylic sheets to size; we also shape them into complex designs. Using state-of-the-art industrial plastic cutting machines, we deliver precise results based on your submitted design and special instructions. Whether you need simple shapes or intricate patterns, we can create exactly what you envision. Applications for Acrylic Sheets Cut-to-order acrylic sheets are ideal for countless applications at home, in offices, schools, and businesses. They are commonly used to replace display cabinet glazing, interior glass panels, walls, windows, and cupboard doors. Acrylic mirror-finished sheets are especially popular in gyms and home fitness studios as they provide a lightweight, cost-effective alternative to traditional glass mirrors. Outdoors, plastic sheets are frequently used for garden mirrors or as replacements for shed and greenhouse windows. While not unbreakable, acrylic sheets offer significantly higher impact resistance than glass and do not shatter into dangerous shards, making them a safer option. If safety is a concern, acrylic is the ideal choice. Plastic sheet is also incredibly easy to clean, maintain and cheap to replace if it becomes damaged. And being able to buy online with delivery anywhere in the Canada makes it an easy and convenient material to use in all sorts of applications, no matter how large or small. A.L.Plastics | Marion Collection | Acrylic Depot

Machined Plastic Parts

About UHMW and HDPE UHMW(Ultra High Molecular Weight) polyethylene plastic is known for its exceptional impact strength, making it one of the most durable thermoplastics available. It also offers outstanding abrasion resistance and tensile strength. Among all polyethylene materials, UHMW stands out with the highest impact strength. It outperforms carbon steel by a ratio of 10 to 1 in some applications. Additionally, it resists stress and cracking while boasting a low coefficient of friction, making it self-lubricating. These properties make it ideal for sliding applications, rough surfaces, or any scenario where reducing friction is essential. HDPE (High Density Polyethylene), while slightly lower in tensile strength compared to UHMW, offers excellent chemical resistance and minimal moisture absorption. This material is widely used in industries that demand impact resistance, high tensile strength, and resistance to chemicals and corrosion. In machining applications, it achieves a finer finish than UHMW, though both materials are easy to machine. Today, various grades of UHMW and HDPE are available to meet specific application needs. For example, anti-static grades of UHMW (AS/UHMW) are used to produce parts that prevent the build-up of electrical charges, making them ideal for sensitive environments. A.L.Plastics | Marion Collection | Acrylic Depot