Cut to size plastic and acrylic fabrication

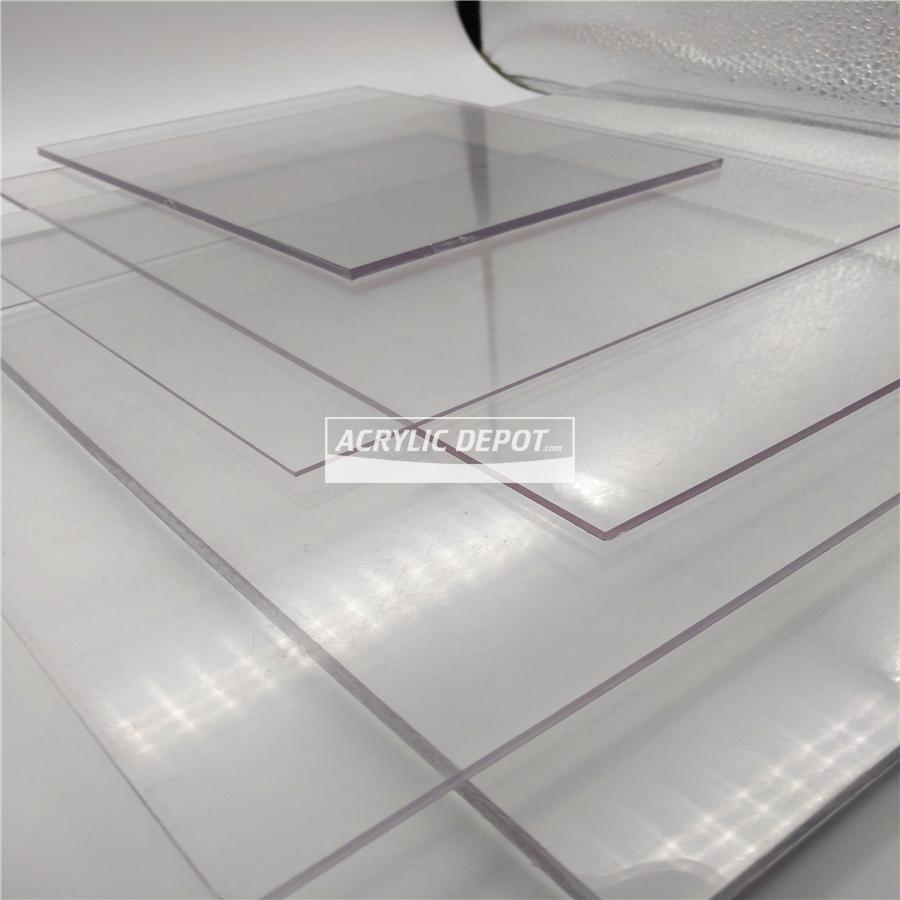

Uses for Plastic Sheeting Acrylic is incredibly versatile and has a wide range of uses. Many household projects and home improvements benefit from colored or clear plastic sheets. For example, homeowners often use high-impact, shatterproof acrylic as a cost-effective and safer alternative to glass for shed or greenhouse windows. Other popular uses include kitchen splashbacks, countertops, table protectors, and picture framing. Larger projects, such as shower tanking and wet-room installations, have also become increasingly common. These durable and stylish sheets can be cut to any size and come in virtually any color, making them both practical and fashionable. Colors and Other Options In addition to clear acrylic (equivalent to Acrylite®), we offer a wide range of colored plastics, including silver and gold mirror finishes. Our plastic sheets (acrylic and polycarbonate) are available in both transparent and opaque varieties. Simply provide the dimensions, color, thickness, and transparency preferences for your custom acrylic sheet order. Cut to Size After receiving your order, we cut and finish the edges of your bespoke plastic sheet to meet your exact requirements. We then wrap and protect your sheets to ensure they arrive at your door in pristine condition. Acrylic sheeting offers several advantages over other materials. It is lightweight, easy to clean and maintain, and can be molded into almost any shape. These qualities make acrylic sheets a perfect choice for various creative and functional projects. From Simple Shapes to Complex Designs We don’t just cut acrylic sheets to size; we also shape them into complex designs. Using state-of-the-art industrial plastic cutting machines, we deliver precise results based on your submitted design and special instructions. Whether you need simple shapes or intricate patterns, we can create exactly what you envision. Applications for Acrylic Sheets Cut-to-order acrylic sheets are ideal for countless applications at home, in offices, schools, and businesses. They are commonly used to replace display cabinet glazing, interior glass panels, walls, windows, and cupboard doors. Acrylic mirror-finished sheets are especially popular in gyms and home fitness studios as they provide a lightweight, cost-effective alternative to traditional glass mirrors. Outdoors, plastic sheets are frequently used for garden mirrors or as replacements for shed and greenhouse windows. While not unbreakable, acrylic sheets offer significantly higher impact resistance than glass and do not shatter into dangerous shards, making them a safer option. If safety is a concern, acrylic is the ideal choice. Plastic sheet is also incredibly easy to clean, maintain and cheap to replace if it becomes damaged. And being able to buy online with delivery anywhere in the Canada makes it an easy and convenient material to use in all sorts of applications, no matter how large or small. A.L.Plastics | Marion Collection | Acrylic Depot

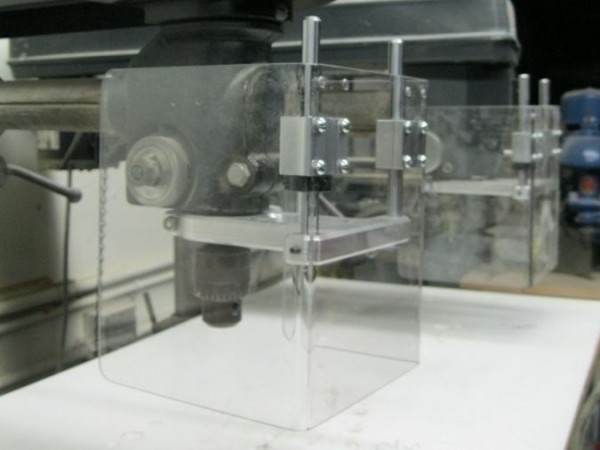

Custom Plastics Machining

Custom Plastics Machining: What to Look for in a Supplier 1. Technology base It will always be preferable to work with suppliers who have the latest CNC production technology allied to skilled workers. These suppliers will be able to produce parts to close tolerances while keeping part quality and finish consistently high. 2. Materials expertise and selection There are a wide variety of plastic materials available on the market today. The best suppliers know their materials and know the latest materials available on the marketplace. These suppliers will be able to provide superior guidance on material selection, ensuring that the right material is chosen for a given application. Choosing the wrong material, or a material which is not exactly right, can result in misapplication challenges later on. 3. Application expertise in custom plastics machining Material knowledge is one thing, application knowledge is another. The latter should always precede the latter. Choose a supplier who knows how to undertake a comprehensive application review to determine how a finished part will be used. A good application review will identify all the requirements that the finished part must satisfy, and is critical for ensuring that the right material is chosen. In addition, some suppliers will specialize in serving a narrow range of industry applications, while other suppliers will serve a broader range. It is important to choose a supplier who has experience in serving your particular application – choosing a supplier with limited experience in servicing your specific application may increase the risk of misapplication issues arising post-sale. A.L.Plastics | Marion Collection | Acrylic Depot