Fabrication

- Home

- Services

- Fabrication

Innovative Plastic Fabrication Services for every need

Crafting Custom Plastic Solutions with Precision

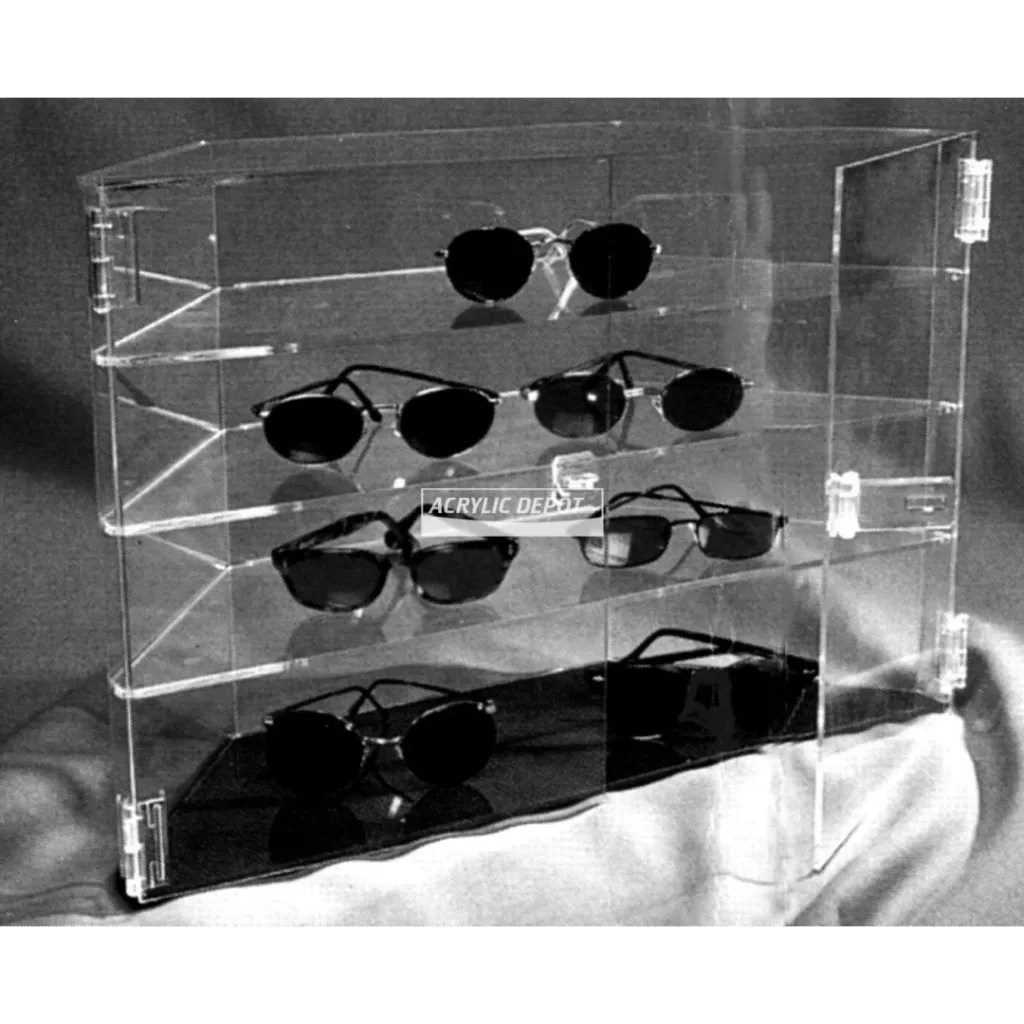

Plastic fabrication is the process of shaping and assembling plastic materials to create custom, functional products. Using advanced techniques, we transform raw plastic into precise parts that suit a variety of industries. Whether it’s a simple cut-to-size piece or a detailed multi-part assembly, plastic fabrication offers solutions that are lightweight, durable, and tailored to each project. At Acrylic Depot, we specialize in plastic fabrication services that ensure every product meets high standards of quality and precision.

Our Fabrication Process – From Concept to Completion

We discuss your goals and requirements to guide material selection.

Using CNC and laser cutting for exact dimensions.

Precision techniques to shape, weld, and assemble components.

Each product undergoes rigorous testing before delivery.

Plastic Fabrication Services | Quick Facts

Techniques Used

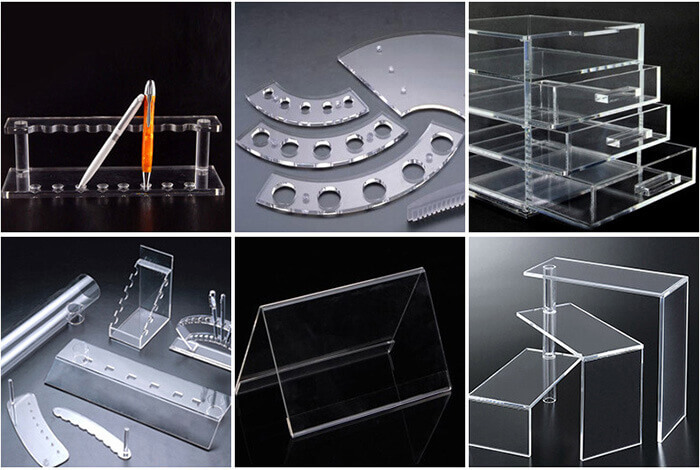

Our plastic fabrication process includes a range of techniques like cutting, welding, forming, and bending to shape plastic precisely according to project needs.

Industries Served

We cater to diverse industries including retail, healthcare, construction, automotive, and more, each with unique requirements for plastic components.

Our Expertise

At Acrylic Depot, our team specializes in advanced methods like CNC machining, laser cutting, and heat forming, ensuring accuracy and quality in every product.

Why Partner with Us?

At Acrylic Depot, we’re committed to delivering plastic fabrication services that stand out for quality, precision, and customer focus. Here’s why clients across industries choose us for their custom fabrication needs.

Expert Guidance

Fast Turnaround

Quality Assurance

Customized Solutions

Our knowledgeable team is here to guide you through every step of the process. From selecting the right materials to finalizing design specifications, we offer professional advice to ensure your project meets both functional and aesthetic goals.

We understand the importance of meeting deadlines. With efficient project management and streamlined production, we complete orders on schedule every time, so you can rely on us to keep your project on track.

Quality is at the core of everything we do. Each product undergoes stringent quality checks to meet high standards, ensuring you receive durable, reliable components that are built to last.

Every project is unique, and so are our solutions. We work closely with you to tailor each product to your exact specifications, creating custom plastic components that align with your specific needs and vision.