How do you cut acrylic mirror sheets?

Cutting acrylic mirror sheets doesn’t have to be difficult. Start by positioning the mirror sheet so that the scored line hangs over the edge of a table. Ensure that the smaller side of the scoring is the one hanging off the edge. Place your palm firmly on the larger side of the acrylic sheet that remains on the table. Hold it down as securely as possible. Grasp the shorter side of the mirror hanging over the table’s edge and apply a swift, firm downward push. Continue pressing down on the scored portion until the piece breaks cleanly away. This method makes cutting acrylic mirror sheets quick and straightforward. For added precision, ensure that your scoring tool is sharp and that you apply consistent pressure while scoring the sheet. Practicing on a small piece before working on your final project can help you perfect your technique. By following this approach, you’ll achieve clean, professional cuts with minimal effort.

Can you melt acrylic sheets?

Acrylic sheets soften at a temperature of 320°F (160°C), but they do not truly melt under normal conditions. This makes them a reliable choice for everyday use without the risk of melting. However, to protect acrylic surfaces from heat damage, avoid placing hot items directly on them. Instead, use a protective trivet or padding with rubber cushions to maintain the quality & durability of the surface.

Is Acrylic Durable?

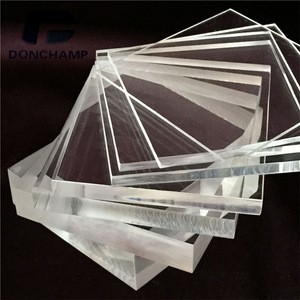

Many industries widely use acrylic, also known as Polymethyl Methacrylate (PMMA), for its exceptional strength, weather resistance, and clarity. But is acrylic durable? The answer is yes. Acrylic is a very flexible material that works well in a wide range of temperatures. It stands up better to weather than most plastics. Its strength makes it a good choice for indoor and outdoor use, lasting a long time in many conditions.

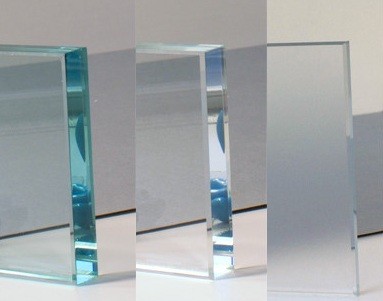

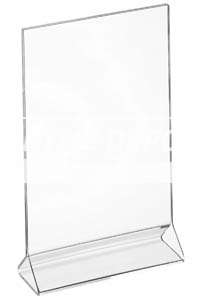

Is acrylic or glass better for framing?

When it comes to framing, both acrylic and glass offer unique benefits, but choosing the right one depends on your needs. Picture Frame Glass is popular for ready-made, inexpensive frames due to its low cost. However, it often has a greenish tint from high iron content, which can affect image clarity. High-end options like museum or water white glass eliminate this tint, providing better visibility. Glass is heavy and prone to breaking, making it less suitable for large frames or shipping. Acrylic is a lightweight and shatter-resistant alternative. It is ideal for larger frames and safe for children’s rooms or spaces prone to vibrations. Acrylic comes in multiple options: Standard Acrylic: A basic, clear option. UV Filter Acrylic: Blocks up to 98% of UV rays to prevent fading. Non-glare Acrylic: Reduces reflections, enhancing visibility in bright spaces. Museums and galleries often prefer acrylic for its safety, as broken glass can damage valuable artwork. Acrylic also reduces shipping costs and risks due to its lighter weight. However, it does have some downsides: it’s more expensive, scratches easily, and may bow over time. For smaller frames or budget-friendly projects, glass works well. For larger frames, UV protection, or added safety, acrylic is the better choice. Consider the environment and artwork’s value to make the right decision on whether you want to choose acrylic or glass for framing.

Are acrylic fish tanks better than glass?

You will have a more clear view of your fish with acrylic tanks. If you want to modify your tank for a sump system or canister filter, drilling into acrylic is easy. You don’t have to worry about cracking or breaking the tank. Acrylic tanks are also very sturdy. In larger sizes, they are less likely to come apart or leak compared to glass. Glass aquariums, however, have some downsides. They are heavier, harder to modify, and can chip or crack easily. Drilling into a glass tank can break a panel. If this happens, you may need to replace the panel or even the entire tank. Glass can also distort the view of your fish. Its green tint might make brightly colored fish look duller. Glass tanks also don’t insulate well. You might see higher electric bills trying to maintain tank temperatures with a heater or chiller. Acrylic fish tanks, on the other hand, have their own drawbacks. They are more expensive than glass and can scratch easily during aquascaping or decoration. Some acrylic tanks may yellow with age due to chemical reactions. Acrylic tanks need a stand to support the entire bottom, or the weight of the water might cause them to crack. They also require more top support to prevent bowing and spilling. Glass tanks have benefits too. They are easier to build, as the panels are sealed with silicone. Glass is cheaper than acrylic and is less likely to scratch during setup. For smaller tanks, glass often looks nicer than acrylic. Acrylic fish tanks, however, are about 50% lighter than glass & provide better insulation. This can help reduce energy costs for maintaining water temperature.

Does acrylic scratch easier than glass?

Acrylic material are very lightweight with smooth corners that do not chip. It also offers a less distorted view than glass. Acrylic needs a stand to support its entire bottom, and its surface scratches easily. Glass is easy to clean because it does not scratch readily, and requires support only along the outside edges. Glass is heavier and the edges can chip.

Which is stronger glass or acrylic?

MachiningGlass can not be easily processed by sawing, milling and bending. Moreover, it is a lot more difficult be form after heating. Scratch resistance Glass is harder to scratch. Acrylic sheets can be supplied with a scratch-resistant coating (hard-coating) which provides extra protection. While scratch-resistant acrylic are not nearly as scratch-resistant as glass. Small scratches in acrylic can be polished. Scratched glass most be replaced. Light transmittance Glass has 90% light transmission, for acrylic it is 92%.Gloss Acrylic provides a softer reflection of light. Station glass and acrylic opposite each other and one is seldom in doubt about what is what. Acrylic with glass look is acrylic added a bit of color so that it even more looks like glass. Weight Acrylic weighs less than half that of glass. Impact Resistance Acrylic is much stronger than glass and thus more resistant to strokes (10-20 times). When acrylic shatter, it is, in contrast to glass, in large pieces with relative blunt edges. At the same time contribute the low weight to make acrylic much safer. UV light Standard acrylic allow as opposed to glass UV light to pass. Acrylic sheets can also be delivered with a UV filter. Insulation Acrylic insulates better than glass, and is used heavily in skylights and doors to coolers. Manufacturing Molding and extrusion of glass items are more expensive and requires much more energy.

Is acrylic or glass cheaper?

Acrylic can actually be more expensive than glass, but offers many advantages. Acrylic is often clearer than glass (which can have a green tint). Due to its lighter weight, acrylic is also more cost effective to ship. Acrylic is also flexible, making it less likely to break than glass. Acrylic weighs less than half that of glass. It is much stronger than glass and thus more resistant to strokes (10-20 times). When it shatters, it forms large, blunt-edged pieces unlike glass. While scratch-resistant acrylic are not nearly as scratch-resistant as glass. There are different kinds of acrylic which are more suitable for different applications. Standard clear acrylic may look too plastic-like to pass as glass at the edges. But when it is used as a glazing material acrylic is very effective. Acrylic expensive than glass, but its strength, clarity, and lightweight properties make it a superior choice for many applications.

Does acrylic turn yellow?

American-made acrylic does NOT yellow in the sunlight. Witness the protective canopies and bubbles in the WWII Plexiglas is a trade name acrylic (extruded or cast medium grade acrylic sheets, rods, tubes) , PVC (type 1 clear, also i the acrylic family), PET (polyester, soad bottle material). Butyrate (mostly extruded tubing), and Polycarbonate (Lexan, Hyloid) are all clear plastic resins with wide a range of properties. My bad on classifying plexi as a polycarb, Plexi is mainly used as a glass replacement or for weight savings. Duh! the hammer isn’t even necessary, just drop both from waist level. Or try to drill Acrylic sheet. ANYWHO! As mentioned, Acrylic aquaria built using quality float cast plastics should give you decades of service if properly cared for (not scratched and gouged). A yellowing can happen, sure if in direct sunlight, overheated, oe bombarded by UV. I think most is USDA approved too (could be wrong, let me know) which means the will not absorb, hold or leach toxic chemicals/materials. 1/2″ Lexan will stop a .45 cal.

Are acrylic sheets breakable?

Acrylic is a transparent thermoplastic homo-polymer known more commonly by the trade name “Plexiglas.” The material is similar to poly-carbonate in that it is suitable for use as an impact resistant alternative to glass. It is generally considered one of the clearest plastics on the market. Some of the first applications were in WWII when it was used for submarine periscopes as well as airplane windows, turrets, and canopies. Airmen whose eyes were injured due to shards of broken acrylic fared much better than those affected by shards of shattered glass. Acrylic in the modern era and in general is used for a variety of applications that typically take advantage of its natural transparency and the impact resistance of certain variants. Common uses include lenses, acrylic nails, paint, security barriers, medical devices, LCD screens, and furniture. Because of its clarity, it is also often used for windows, tanks, and enclosures around exhibits.