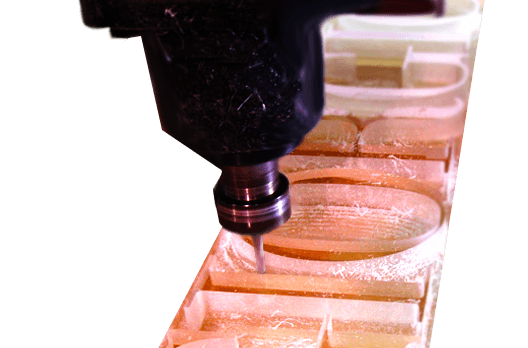

What kind of drill bit is used for plexiglass?

What kind of drill bit is used for plexiglass? Plastic drill bits can drill through plastic. These metal drill bits have ground flukes with 90 degree points and 0 degree rake. Plastic drill bits shave or scrape plexiglass, acrylic or plastic away layer by layer. These bits come in a variety of diameters at home improvement or hardware stores. If you are unable to find them locally, many online retailers sell them. Plexiglass is a clear, plastic, lightweight alternative to glass. Drilling holes in plexiglass can be challenging. Often the traditional drill bits, used for metal and wood, chip and crack it while drilling through its surface. Specialty drill bits prevent the cracking and chipping. You can also alter traditional drill bits to work better with plexiglass.

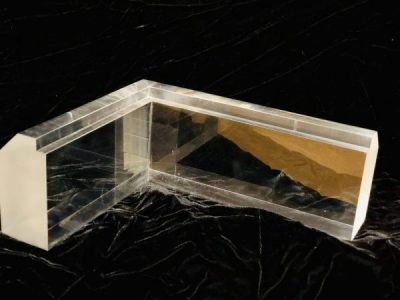

What glue do you use to stick acrylic to wood?

A clear-drying epoxy glue. Note that not all epoxies are equal. In a general sense they can glue acrylic materials together with ease.

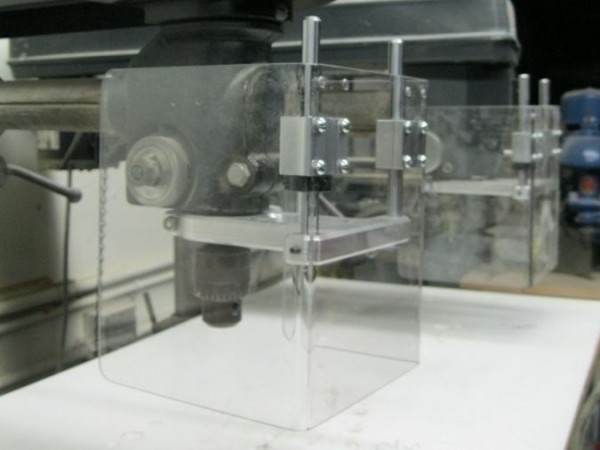

What screws to use with plexiglass?

First, determine the correct screw size to use. Start by drilling a small pilot hole with a low-diameter drill bit. Gradually increase the drill bit sizes until you reach your desired diameter. Drilling a pilot hole and immediately switching to a large drill bit can crack the plastic.

Is PVC and acrylic the same?

PVC Acrylic PVC and Acrylic are not Similar. Polyvinyl carbonate (PVC) is a strong thermoplastic material commonly used for manufacturing different parts of instruments like insulation of cables, pipes, medical equipments, wire, etc. PVC and Acrylic serve distinct purposes in various industries due to their unique properties. PVC is the world’s most produced synthetic polymer plastic. This material shows great performance while being used for manufacturing other materials or tools. However, this has some disadvantages too. It is not heat-resistant. You need to be careful while machining a PVC plastic because this can resist heat up to 84° C. However, the durability and quality of PVC plastics in building materials are worth appreciation. Acrylic is an extremely transparent kind of plastic. It has low turbidity, is easy to process, and is also good at withstanding high temperature. It can stand up to strong ultraviolet sunlight exposure and is able to resist solvents and chemicals. Acrylic plastics do not tend to yellow or weather around the edges and are shatterproof as well. The weakness of acrylic is poor impact resistance, but it can also be improved in order to meet a request for production. In summary, while both materials are versatile, their distinct properties highlight that PVC and Acrylic are not similar.

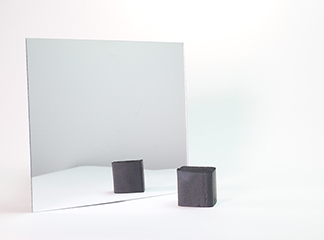

What’s an acrylic mirror?

Acrylic Mirror is lightweight, making it easy to deliver and install. It is a preferred choice for schools, hospitals, and homes with young children where safety is essential. Traditional mirrors are often made from glass, but acrylic mirrors are now a popular alternative. They are durable, high-quality, and can be shaped into decorative pieces using modern technology. Acrylic is stronger and more impact-resistant than glass. It is also cost-effective, lightweight, and requires minimal maintenance, making it a versatile option for various applications.

How heavy is acrylic?

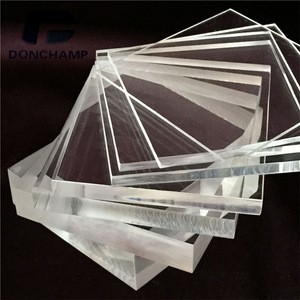

How much do the acrylic sheets weigh? Acrylic weight depends on their thickness and total area of sheet. If sheet is more than half inch thick and 4′ x 8′ area then it is heavy to lift by a person. Inch Millimeter Cast, Extruded & Abrasion Resistant Acrylicweight per square foot 1/16”(.060”) 1.5 0.365 5/64”(.080”) 2.0 0.471 1/10”(.098”) 2.5 0.582 1/8”(.118”) 3.0 0.694 3/16”(.177”) 4.5 1.071 1/4″(.236”) 6.0 1.424 3/8”(.354”) 9.0 2.136 1/2″(.472”) 12.0 2.879 3/4″(.708”) 18.0 4.322 1”(.944”) 24.0 5.759

Are acrylics bendable?

Yes, acrylics bend easily, is fully clear, and resists, and resist breaking well. Acrylic weighs half as much as glass and stays strong against natural elements.

Can acrylic shatter?

Acrylic is widely used for its strength and durability, making it an excellent alternative to glass in many applications. But can acrylic shatter? The answer is: Rarely. With high impact resistance, acrylic doesn’t shatter like traditional glass. If it does break under extreme force, it fractures into large, dull-edged pieces, reducing the risk of injury. Unlike acrylic, laminated glass consists of multiple layers of mineral glass fused together with transparent liners made of materials like PVB or SGP. These liners enhance the strength of glass, preventing inclusions and making it more robust. Among these, SGP is the preferred liner due to its hydrophobic properties. It improves its durability and resistance to environmental factors. While laminated glass has its advantages, acrylic stands out for its lightweight nature, affordability, & safety. Its shatter-resistant properties make it ideal for applications like protective barriers, signage, and displays where both durability and safety are priorities. Acrylic is designed to withstand significant impact, making it a reliable, safer choice for both residential and commercial uses.

Can you melt acrylic sheets?

Acrylic sheets soften at a temperature of 320°F (160°C), but they do not truly melt under normal conditions. This makes them a reliable choice for everyday use without the risk of melting. However, to protect acrylic surfaces from heat damage, avoid placing hot items directly on them. Instead, use a protective trivet or padding with rubber cushions to maintain the quality & durability of the surface.

Is Acrylic Durable?

Many industries widely use acrylic, also known as Polymethyl Methacrylate (PMMA), for its exceptional strength, weather resistance, and clarity. But is acrylic durable? The answer is yes. Acrylic is a very flexible material that works well in a wide range of temperatures. It stands up better to weather than most plastics. Its strength makes it a good choice for indoor and outdoor use, lasting a long time in many conditions.