What is the difference between plastic and acrylic?

Yes, there is a difference between acrylic and plastics. They are both in the polymer family. Acrylic is a mixture of monomer and polymer. clear plastic is one of the most popular materials used in manufacturing and design. However, there is a wide variety of these transparent polymers out there, and they can’t always be used interchangeably. Plastic, after all, is a generic term for a large family of synthetic or semi-synthetic materials. Acrylic Acrylic is kinds of thermoplastics that are petroleum based and created from the derivation of natural glass. It is also known as polyacrylate. Polycarbonate Poly-carbonates are easy to mold, work and clear thermoplastic that has incredible durability , and so is used for a great many purposes, such as in the construction industry and the creation of safety glasses. It’s more expensive than Plexiglas, but also stronger and can also be bent at room temperature. Poly-carbonate is available under brand names like Lexan and Makrolon.

Are there different types of Plexiglas?

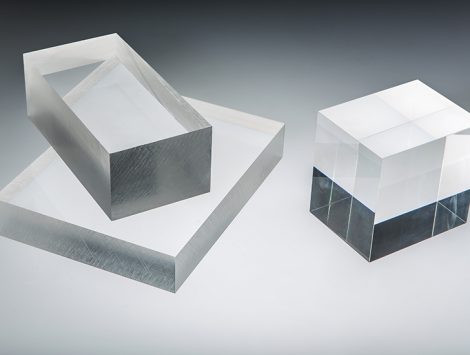

There are three main types of Plexiglas Cell Cast Acrylic Sheet, Continuous Cast Acrylic Sheets, Extruded Acrylic Sheets. Cell Cast Acrylic Sheet This style is produced by melted liquid PMMA resin poured between two plates of glass Least amount of expansion and contraction Highest margin of error on thickness tolerance Standard thickness tolerance from .118” – .500” is +/- 8% This is the best material to use when cutting or routing Highest molecular weight Widest range of colors available Standard material for signs, aquariums, and high-end fabrication Continuous Cast Acrylic Sheets This style is produced by pouring melted liquid PMMA resin between two belts of polished stainless steel Best material consistency Least amount of expansion and contraction 2nd best thickness tolerance Widest ranges of sizes available up to 9’ wide and 16’ long Standard material for forming, fabrication, and skylights Extruded Acrylic Sheets Semi-soft melted resin is pushed between rollers and cut to size Highest internal stress within the sheet Most expansion and contraction Generally, the best thickness consistency Thickness tolerance +/- 10% Softest sheet Gums up routers more when cutting Easy to glue Standard material for displays, and replacement windows. Some signage applications.

Is plexiglass the same as acrylic?

Acrylic Acrylic is manufactured in one of two ways. It is either extruded or cell cast. The extrusion method is a less expensive way to manufacture acrylic but presents two problems. Extruded acrylic is softer than cell cast acrylic, which means it is more susceptible to scratching. And extruded acrylic can have impurities in its surface. Cell cast acrylic has a harder surface because of the casting process. When acrylic is cell cast it is formed in a closed area, which reduces the chances of impurities becoming lodged in the material. Plexiglas Plexiglas is the original trade or brand name for this type of acrylic. Plexiglas is a cell cast acrylic, so it has fewer impurities (tiny ripples or embedded specks). The manufacturing costs are higher with cast acrylic, which is reflected in its higher price. The term Plexiglass is more commonly used for this type of acrylic.

How much does acrylic sheet cost?

Plexiglas sheets have many characteristics and features that are well-suited to applications across a wide range of industries, including construction, glazing, retail, machining, plastic fabrication, recreation, signage, and much more. We are pleased to offer cut-to-size acrylic sheets in a wide range of colors, grades, and sizes from industry leaders in Plexiglas Our customers use acrylic Plexiglas in commercial construction, home improvement projects, laser engraving, furniture making, merchandising, and other uses.

How do you cut and shape acrylic?

Plexiglass, also known as acrylic glass, is a plastic substance made from primarily acrylic. It is more durable than glass, easier to cut, and easier to replace. However, cutting it can be tough if you have never done it before. A plastic-scoring blade can be used. With a straightedge as a guide, pull the blade toward you, leaving a score mark. Score the acrylic several more times along the same line, then place the acrylic on the edge of the table and use light, quick pressure to snap the piece in two. You can also cut acrylic with more traditional blade tools such as a jigsaw, band saw, or table saw.