Does acrylic turn yellow?

American-made acrylic does NOT yellow in the sunlight. Witness the protective canopies and bubbles in the WWII Plexiglas is a trade name acrylic (extruded or cast medium grade acrylic sheets, rods, tubes) , PVC (type 1 clear, also i the acrylic family), PET (polyester, soad bottle material). Butyrate (mostly extruded tubing), and Polycarbonate (Lexan, Hyloid) are all clear plastic resins with wide a range of properties. My bad on classifying plexi as a polycarb, Plexi is mainly used as a glass replacement or for weight savings. Duh! the hammer isn’t even necessary, just drop both from waist level. Or try to drill Acrylic sheet. ANYWHO! As mentioned, Acrylic aquaria built using quality float cast plastics should give you decades of service if properly cared for (not scratched and gouged). A yellowing can happen, sure if in direct sunlight, overheated, oe bombarded by UV. I think most is USDA approved too (could be wrong, let me know) which means the will not absorb, hold or leach toxic chemicals/materials. 1/2″ Lexan will stop a .45 cal.

Are acrylic sheets breakable?

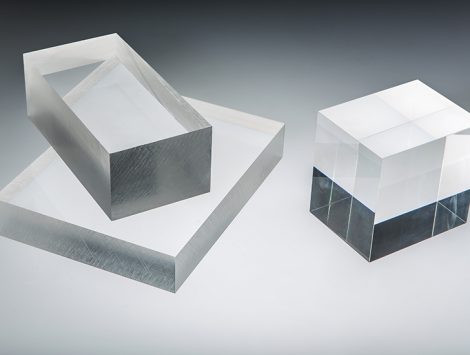

Acrylic is a transparent thermoplastic homo-polymer known more commonly by the trade name “Plexiglas.” The material is similar to poly-carbonate in that it is suitable for use as an impact resistant alternative to glass. It is generally considered one of the clearest plastics on the market. Some of the first applications were in WWII when it was used for submarine periscopes as well as airplane windows, turrets, and canopies. Airmen whose eyes were injured due to shards of broken acrylic fared much better than those affected by shards of shattered glass. Acrylic in the modern era and in general is used for a variety of applications that typically take advantage of its natural transparency and the impact resistance of certain variants. Common uses include lenses, acrylic nails, paint, security barriers, medical devices, LCD screens, and furniture. Because of its clarity, it is also often used for windows, tanks, and enclosures around exhibits.

How do you bend acrylic plastic sheets?

To Bend Acrylic Sheet You Will Need: Heat Source – Small projects with bends that are close together will need upon heat source which can be easily aimed at small areas. The two best tools for this are a small butane torch, the type used in the kitchen work well, or you can also use an embossing heat tool, used by card makers and scrap bookers to melt and apply embossing powders. For larger projects, it is possible to use a heat gun, of the type used by airplane modelers to apply shrink plastic coatings, or a paint stripping heat gun or regular propane torch. Hair dryers will not achieve the level of heat required for anything more than very thin sheet acrylic and will move too much air to be of much use working with thin materials. Clamps – We like using quick release bar clips but you can use anything that will hold your scrap strip wood in place as a bending jig. Scrap wood – You need a straight-edged piece of wood for your jig; we suggest something at least 1/8 inch thick and wide enough for your clamps. You will also need spacers the same thickness or slightly thinner than the plastic you need to clamp, to keep your strip-wood jig even with the top of the plastic you will be bending. You also need a heatproof work surface or a scrap of MDF or plywood to act as a work surface you can clamp your bending jig to. Plexiglas or Acrylic Sheet – This system works well for small pieces of Plexiglas in thicknesses of up to 1/8 inch. For thicker acrylic, you will need to use a metal bar clamped very securely, and you may only be able to work with narrow strips of material as your heat source may not be able to heat wider areas of thick material. Protective Equipment – Hot plastic can be dangerous. Always work in a well-ventilated area away from flammable materials, other than those you will be working with. Wear eye protection, and use welding gloves or kitchen oven gloves to protect your hands from burns.

Is acrylic stronger than polycarbonate?

Polycarbonate (Lexan) and acrylic sheet (Lucite or Plexiglas) are two of the most frequently used see-through plastics. Each of the two have benefits and drawbacks. Acrylic is shinier and polycarb is stronger. Acrylic is less expensive but easier to crack. Polycarb is more impact resisant but easier to scratch. They are both stronger and lighter than untempered glass Acrylic is 4x to 8x stronger than glass, while polycarb is about 200x stronger.

What is the difference between plastic and acrylic?

Yes, there is a difference between acrylic and plastics. They are both in the polymer family. Acrylic is a mixture of monomer and polymer. clear plastic is one of the most popular materials used in manufacturing and design. However, there is a wide variety of these transparent polymers out there, and they can’t always be used interchangeably. Plastic, after all, is a generic term for a large family of synthetic or semi-synthetic materials. Acrylic Acrylic is kinds of thermoplastics that are petroleum based and created from the derivation of natural glass. It is also known as polyacrylate. Polycarbonate Poly-carbonates are easy to mold, work and clear thermoplastic that has incredible durability , and so is used for a great many purposes, such as in the construction industry and the creation of safety glasses. It’s more expensive than Plexiglas, but also stronger and can also be bent at room temperature. Poly-carbonate is available under brand names like Lexan and Makrolon.

Are there different types of Plexiglas?

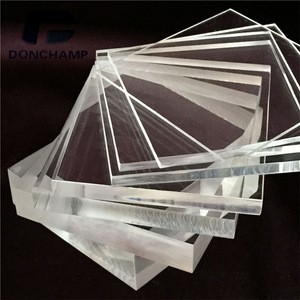

There are three main types of Plexiglas Cell Cast Acrylic Sheet, Continuous Cast Acrylic Sheets, Extruded Acrylic Sheets. Cell Cast Acrylic Sheet This style is produced by melted liquid PMMA resin poured between two plates of glass Least amount of expansion and contraction Highest margin of error on thickness tolerance Standard thickness tolerance from .118” – .500” is +/- 8% This is the best material to use when cutting or routing Highest molecular weight Widest range of colors available Standard material for signs, aquariums, and high-end fabrication Continuous Cast Acrylic Sheets This style is produced by pouring melted liquid PMMA resin between two belts of polished stainless steel Best material consistency Least amount of expansion and contraction 2nd best thickness tolerance Widest ranges of sizes available up to 9’ wide and 16’ long Standard material for forming, fabrication, and skylights Extruded Acrylic Sheets Semi-soft melted resin is pushed between rollers and cut to size Highest internal stress within the sheet Most expansion and contraction Generally, the best thickness consistency Thickness tolerance +/- 10% Softest sheet Gums up routers more when cutting Easy to glue Standard material for displays, and replacement windows. Some signage applications.

Is plexiglass the same as acrylic?

Acrylic Acrylic is manufactured in one of two ways. It is either extruded or cell cast. The extrusion method is a less expensive way to manufacture acrylic but presents two problems. Extruded acrylic is softer than cell cast acrylic, which means it is more susceptible to scratching. And extruded acrylic can have impurities in its surface. Cell cast acrylic has a harder surface because of the casting process. When acrylic is cell cast it is formed in a closed area, which reduces the chances of impurities becoming lodged in the material. Plexiglas Plexiglas is the original trade or brand name for this type of acrylic. Plexiglas is a cell cast acrylic, so it has fewer impurities (tiny ripples or embedded specks). The manufacturing costs are higher with cast acrylic, which is reflected in its higher price. The term Plexiglass is more commonly used for this type of acrylic.

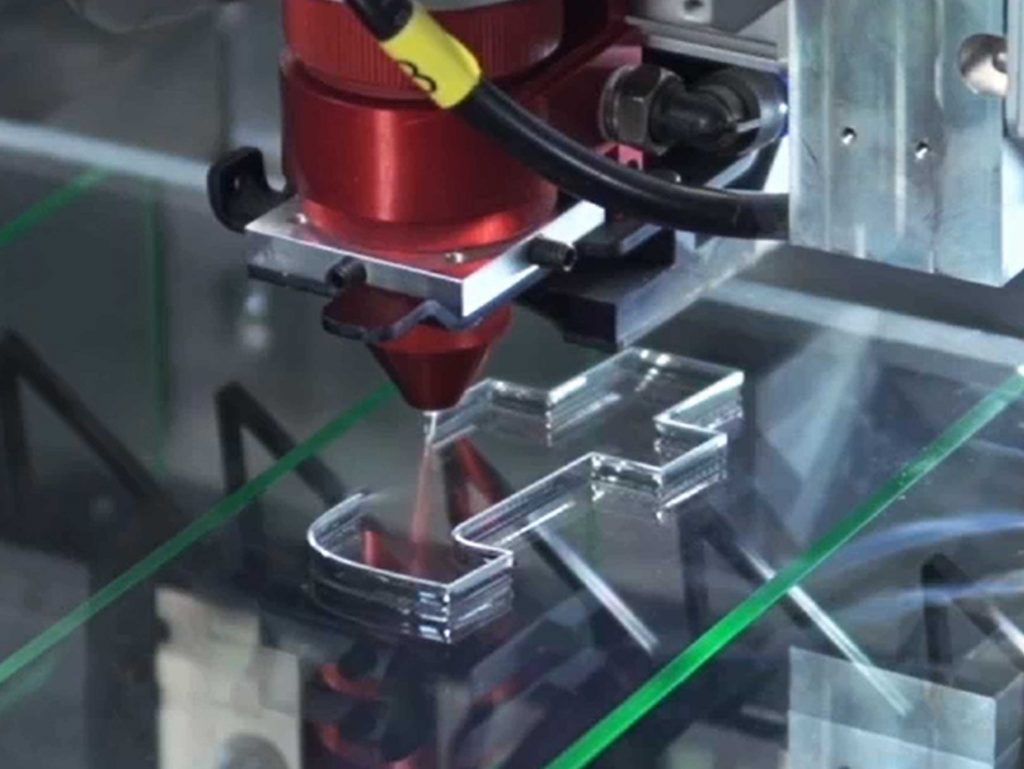

Laser cutting process for acrylic ( Lucite ) sheets

1. Define Your Cutting Expectations Before cutting acrylic, you must first determine your expectations for the final product. Does the end result need a flame-polished, optical-quality finish? Or is the part intended for mechanical use, where edge quality is less critical? This decision will help you choose the appropriate cutting method. For example, if edge quality isn’t a priority, you can save significant time by opting for a less refined cut. 2. Understand the Laser Cutting Process Laser cutting works by vaporizing the solid acrylic material. The laser’s energy causes the acrylic to transition from solid to liquid and then to vapor. This process involves minimal chemical degradation, ensuring a clean cut. However, laser cutting generates a large amount of vapor, which requires an efficient vacuum system to remove it. Importantly, the vapor produced during laser cutting is highly flammable. To prevent accidents, never leave the laser system unattended when cutting acrylic. 3. Use Airflow to Enhance Cutting Quality A gentle stream of air or nitrogen helps blow vapor away from the cutting area. This airflow not only prevents the vapor from igniting but also solidifies the liquid along the cut line. When done correctly, it creates a glossy, flame-polished finish on the cutting edge. However, excessive air pressure can disrupt the solidification process, resulting in a frosted or wavy edge. To avoid this, use an air assist pump with a variable pressure regulator. This allows you to control the airflow and achieve the best results. 4. Choose High-Quality Materials The foundation of a good cut lies in the quality of the material. Using name-brand acrylics ensures optimal results, as these materials are consistent and reliable. Trusted brands like Trotec offer superior performance and are recommended for achieving professional-grade cuts. Brand Manufacturer Plexiglas® / Acrylite® Evonik Perspex® Lucite Altuglas® Akemar Plazit® Plazit Quinn® Quinn Oroglas® Oroglas Types Of Acrylic There are two main types of acrylic that you will commonly encounter, cast and extruded acrylic. These two types of acrylic have slightly different chemistry and are manufactured differently, which results in vastly different cutting characteristics. For most applications, cast acrylic is probably the right material for you, but under specific circumstances extruded acrylic might have its advantages over cast acrylic. The main differences are listed in the table below. Cast Extruded General Many colours available More expensive More thickness’s available (2mm to 200mm) Greater thickness tolerance (>±5%) Less colours available Cheaper Less thickness’s available (30μm to 25mm) Lower thickness tolerance (<±5%) Laser Engraving has high contrast No bur on cut edge High molecular-weight Needs more power – higher melting point Parameters more critical for flame polishing Engraving has low contrast Sharp bur at laser cut line Low molecular-weight Needs less power – lower melting point Parameters not as critical for flame polishing Laser Power As a typical rule of thumb for every 10 Watts of power you will be able to cut 1mm / 0.04 inch of material. This will give you the ability to flame polish your cuts and give good production speed. That doesn’t mean you can’t cut 12mm / 0.5 inch with a 60 Watt laser, this is still possible, but the quality of the cut will not be nice and the process will be much slower. As a general rule, more power is always better; this gives you the versatility to cut extremely fast on thin materials and give you much better cut quality on thicker materials, peak power is the key! Frequency Depending on the material and the type of cut you would like to achieve, the frequency value will change. Flame Polished Cut Common to start with high frequencies (20 to 25 kHz) for cast acrylic. Common to start with low frequencies (2-5 kHz) on extruded acrylic. Separation Cut Common to start with frequencies (9 to 12 kHz) for cast acrylic. Common to start with frequencies (5 to 10 kHz) for extruded acrylic. By decreasing the frequency of the laser you are essentially reducing the cutting energy of the laser, this is done by reducing the amount of laser pulses over a given time frame. This can however help reduce flaming, decrease boiling but does result in slower cutting speeds. The cutting speed is defined by two factors, the quality requirements and the laser power. The typical types of cuts and their speed are shown in the image above. The light blue line represents a separation cut, which is a cut with no preference for edge quality. The second type of cut is represented by the dark blue line which is a quality cut. As you can see there is a large discrepancy in speed of the cut depending on the quality level you would like to achieve with a given thickness of material. There is also a linear increase in speed as the power of the laser increases. For example a 400W laser cutting 10mm thick acrylic will be twice as fast as a 200W laser cutting the same material. Lenses and Focus Lenses are an important factor in the cutting process of acrylics, they have different focal lengths which affect their beam radius and waist length. Without getting too technical, the lenses are responsible for the shape and quality of the cutting edge. For materials up to 20mm / 0.75 inch in thickness you should use a 2.5″ lens if the power of your laser permits this. For lasers with power levels <120 Watts you will notice a dramatic cut quality increase if you linearly increase the lens focal value as the material thickness increases. Trotec laser offers lens options from 1.5″ all the way up to 5″ versions. For materials of 3 to 6 mm (1/8 to 1/4 inch) in thickness you will be able to cut faster using a 2″ lens. For material above 20mm / 0.75 inch in thickness or if your laser power exceeds 200 Watts, using a 5″ lens will give best results. As for focus, for best results, follow these rules. Do not defocus the laser if the material you are

Benefits of Using Acrylic Sheets

Top 5 Benefits of Using Acrylic Sheets Acrylic plastic has gained immense popularity over the years, particularly among businesses. Its strength, versatility, and reliability make it a preferred material for enhancing the durability of various products. Acrylic is also highly scratch-resistant, and some types can even withstand bullets. Additionally, acrylic sheets can be injected with colors, offering a full spectrum of transparent, translucent, and opaque options to suit different requirements. Before purchasing it, ensure you conduct thorough research online. Consider factors like cost, quality, and specific needs before making a decision. Many people prefer acrylic sheets over glass because they share similar properties while being more durable and cost-effective. It also serve as an excellent replacement for glass in many applications due to their durability and versatility. A.L.Plastics | Marion Collection | Acrylic Depot